English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

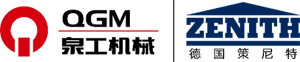

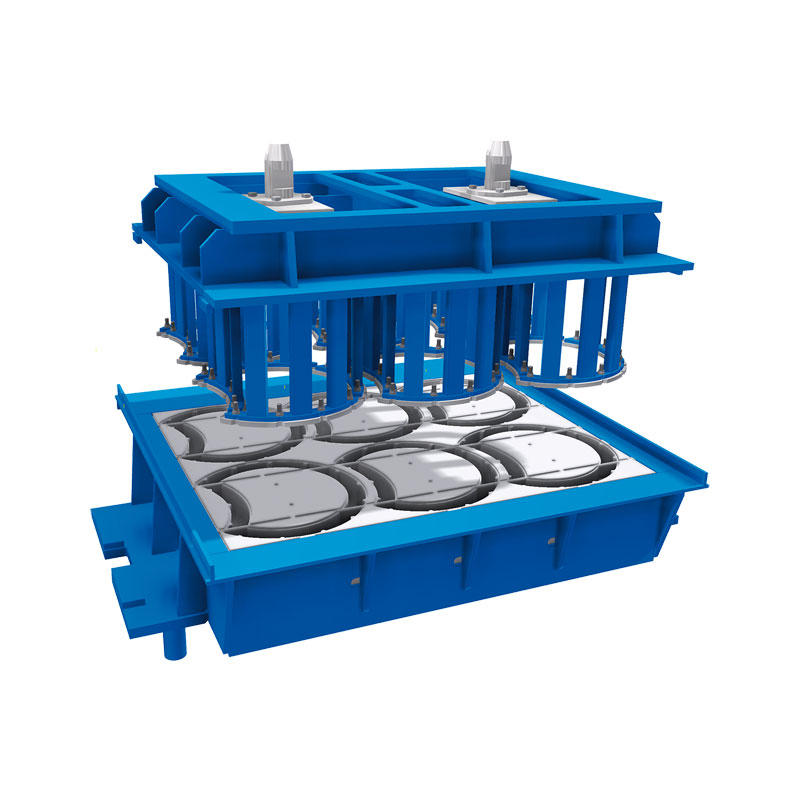

Paver Mold

Send Inquiry

Semunhu anogadzira nyanzvi, isu tinoda kukupa iwe per mold. QMO per Mold At Goved Low Carbon Alloy Simba Simbi uye Inosimbisa Chaive Wiring Concalhilogyhight Aya matekinoroji anogona kugadzira vanyengeri veContion uye geometric maumbirwo.3-0m, neyekutanga vertical makona uye: madonhwe emvura. Pavers yakagadzirwa neQMS ndeye nyore-inonyora, yakanyanya kujeka, hapana burr kutenderera. Molds inogona kuziva diderur freesurface dhizaini uye kudzvinyirira mahwendefa ekubatanidza dhizaini.

Kuti kuve nechokwadi chekugara kwehukuro, QGM paver mold inotora carbunizing treatment., mold framies uye pressure plates dzakaomeswa 60-63HRC, uye mirnimuim kuomesa kudzika i 1.2m. Maererano nezvikumbiro zvevatengi, mold inogona kugadzirwa uye inogadzirwa ne welding kana modular thread locking.

Isu tinopa emhando yepamusoro Paver Molds kune ese marudzi emakina uye maturusi ekushandisa mune inotevera dhizaini:

A) MOULD DESIGN FLAME CUT

Nhete dzewebhu dzinogoneka

Kushandiswa kwakakwana kwe mold

Machine inotsamira chitambi shangu clearance ye0,2-0,5 mm

Counter-conical side madziro zvinogoneka

Hapana ma grooves anodiwa

Yakajairika dhizaini yemashini ekugadzira multilayer

Optional kubvisa pepa dhizaini

Ne digitalization yemahara dhizaini inogoneka

Heatable chitambi shangu dhizaini inoshanda

B)MOULD DESIGN MILLED

Inoshanda kune ese contours uye geometries

Kushivirira mubhokisi rekuumbwa pazasi +/-0.3 mm

Machine inotsamira chitambi shangu clearance ye0,2-0,5 mm

Chaiyo vertical, angled uye yakatsetseka madziro emadziro

Easy demoulding

Kururama kwepamusoro kwekukodzera

Space holders mune zvese zvinogoneka dhizaini zvinogoneka

Optional kubvisa pepa dhizaini

Ne digitalization yemahara dhizaini inogoneka

Heatable chitambi shangu dhizaini inoshanda

Pfeka dziviriro kune ese mavhuvhuvhu anoumbwa seanotevera:

A) CARBURIZING(62-68 HRC)

Mold box uye chitambi shangu dzakaomeswa (62-68 HRC)

Kuomarara kupinda min. 1,2 mm

B)NITRATING (62-68 HRC)

Mold bhokisi uye chitambi shangu nitrate (62-68 HRC)

Kuomarara kupinda min. 0,4 mm

Kashoma chero kushushikana kwemukati kana zvichienzaniswa nekuumbwa kunobatwa ne carburizing

Inokurudzirwa kune diki webhu gobvu

Yepamusoro contour kurongeka pamusoro pezviumbwa zvakabatwa ne carburizing

Kutevera zvinodiwa kubva kune vatengi, molds edu anogona kugadzirwa uye kugadzirwa mu weld kana modular screw thread yekuvhara nzira.